It s fully compatible with Futaba controllers, you may conveniently use in your projects or RC.

#Sg90 servo motor arduino pro#

With this done, we proceed to the void setup() function. Tower Pro SG90 is an ideal servo motor for little mechanism. Next, we create an object of the library, to be used as a reference for controlling our servo motor throughout the code.

#Sg90 servo motor arduino code#

We start the code for the project by including the libraries that we will use which in this case is the servo.h library.

#Sg90 servo motor arduino download#

The library comes pre-installed in the Arduino IDE removing the need for us to download and install. The library makes it easy to turn the servo at different angles using a single command. The code for this project is quite easy thanks to the very comprehensive and concise servo.h library developed by the Arduino team to facilitate the use of servo motors in Arduino projects. With the connection all done, we can now proceed to write the code for the project. Servo directions are sent from the microcontroller to the servo motor as PWM pulses. The signal pin was connected to the digital pin 8 of the Arduino because it is a PWM pin.

Schematicsįor emphasis, the connection is further described below. The Signal pin is the one used to feed the control signal from the microcontroller to the servo, to get the servo rotate to a particular angle.Ĭonnect the Servo to the Arduino as shown in the schematics below.

Servo motors generally have three pins/wires, this includes the VCC, GND, and the Signal pin. The schematics for this project is quite simple as we will be connecting just the servo motor to the Arduino. The following components are required to build this project:Įach of these components can be bought via the link attached to them.

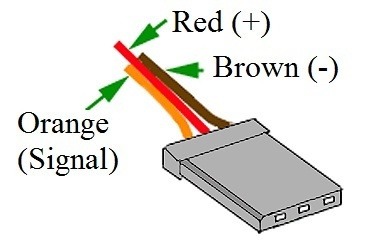

Since we will be using just one servo in this tutorial its fine to power it with an Arduino. Servo’s have high current requirement so when using more than one servo motor with the Arduino, it is important to connect their power connections to an external power supply as the Arduino may not be able to source the current needed for the servo. Used as actuators in many robots like Biped Robot, Hexapod, robotic arm etc.For this tutorial, we will be using the popular SG90 servo motor and our goal will be to rotate the servo motor from one end to the other.So, by varying the on-time from 1ms to 2ms the motor can be controlled from 0° to 180°. So when the on-time is 1ms the motor will be in 0° and when 1.5ms the motor will be 90°, similarly when it is 2ms it will be 180°. Out of which the On-Time can vary from 1ms to 2ms. The PWM signal produced should have a frequency of 50Hz that is the PWM period should be 20ms.Hence we need something that could generate PWM signals to make this motor work, this something could be anything like a 555 Timer or other Microcontroller platforms like Arduino, PIC, ARM or even a microprocessor like Raspberry Pie. Connect the cables to the Arduino as follows. The servo motor only has three cables: power (usually in red), ground (usually in brown) and signal (usually in orange). This can damage the Arduino MG996 instant high torque. I suggest you use external power to the servo. Different shafts of SG90 Then, we need to connect the servo to the Arduino. You not connect directly the servo motor to arduino. To make this motor rotate, we have to power the motor with +5V using the Red and Brown wire and send PWM signals to the Orange colour wire. The SG90 comes with different shafts, so you can choose the most suitable one for your projects.So if you suspend the load at 0.5cm then the motor can pull a load of 5kg similarly if you suspend the load at 2cm then can pull only 1.25 2.5kg/cm torque means that the motor can pull a weight of 2.5kg when it is suspended at a distance of 1cm.It can also be used in robotic arm, CNC machine, Steering systems on RC cars and other robotic or automation applications as well. This servo motor can lift a maximum of 1.6 kg when suspended at 1cm distance from the shaft.This angular position control is performed by PWM technique so by varying its duty cycle you can control the angular position of the motor. The servo motors usually provide control over 180° range.The servo motors are used for control applications which require precision control like robot arm positioning, tool position in machining equipment.The Tower Pro SG90 9g mini servo motor is the most commonly used servo motor in RC applications.Electrical pulses, from your Arduino Uno board, can control it to the. Tower Pro SG90 Servo Motor – 9g Mini/Micro Servo Motor The SG90 servo motor is a geared motor that can only rotate in a 180 degrees range.

0 kommentar(er)

0 kommentar(er)